Case Study:

Control of the heat recovery system

Intuitively controlled, simply regulated

Washing, drying, ironing – the laundry Bauer from Großwechsungen offers professional textile cleaning for private households and companies. As a modern family business, the Thuringians have been relying on heat recovery for a few years now. The heat recovery system is controlled by the multifunction controller (MFC) from HESCH. The intelligent controller enables laundry experts to create complex automation sequences themselves, even without PLC and programming knowledge.

Using waste heat and generating energy

Dry cleaners and laundries have high energy requirements: on average, they spend a good 10 percent of their total costs on energy and water. This makes them one of the most energy-intensive sectors in the skilled trades. The majority – 85 to 90 percent – is required for the generation of thermal energy, for example to heat the washing lines, washing machines, ironers and dryers, as well as for processes such as ironing and forming. This produces waste heat that usually escapes unused into the open air – a waste of resources that is neither good for the environment nor good for the wallet. Because waste heat is valuable energy.

With a heat recovery system, it can be captured and made usable again. This significantly reduces energy consumption and operating costs.

Control of the heat recovery system without PLC

The Bauer laundry in Großwechsungen on the southern edge of the Harz Mountains also works continuously to optimise processes and reduce costs. This modern family business collects, delivers and processes in-house and rental linen for hotels, guesthouses, restaurants, households, public institutions, businesses and nursing homes.

To increase efficiency, the Thuringians decided some time ago to install a heat recovery system. There were plenty of such systems on the market. But virtually all manufacturers insisted on using their own programmable logic controller (PLC).

However, these PLCs were too expensive and inflexible for my purposes.

Lothar Bauer (owner)

As a trained electrician, he is familiar with the subject matter, but has no special programming knowledge – but without this you won’t get very far with a PLC.

"There is a constant need for improvement in my laundry. Therefore, I must be able to constantly expand, control, monitor and regulate."

Lothar Bauer

“I would like to do this myself without having to hire a PLC programmer every time,” says Lothar Bauer.

So Bauer set out to find a plant manufacturer who would only supply him with the heat recovery technology (without a PLC) and an intelligent controller that would give him the freedom he wanted.

Less is more

During his Internet research, he came across the multifunction controller (MFC) from the HESCH company and was immediately enthusiastic:

With the MFC, you can create, optimize and monitor sequence controls yourself - without having to have a degree in programming.

Lothar Bauer

“This is exactly what I was looking for,” said Lothar Bauer.

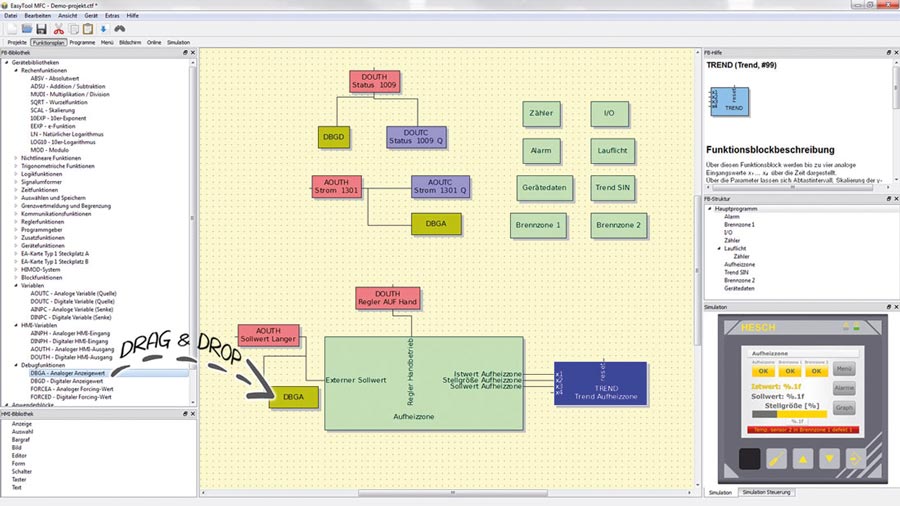

The MFC is modularly expandable and offers simple commissioning, intuitive operation and a wide range of communication interfaces (PROFINET, PROFIBUS, Modbus, CAN bus, HPR bus). In addition, an extensive function library with over 100 ready-made functions is available. These can be assembled on the PC simply by drag & drop to the desired process flow. Programming knowledge is not required. This saves time and costs.

All-rounder for all control and monitoring tasks

In the meantime, the MFC from HESCH has been in use in the Großwechsungen laundry for over two years. There he controls and monitors the complete heat recovery system.

It ensures that the two heat exchangers work efficiently and ensures that there is always enough hot water for production. In addition, he manages the supply of heating energy to other company buildings (dining room, changing rooms, offices) and the adjacent residential building. For this purpose, the MFC measures the temperatures at several points in the process and controls (opens / closes) the 3-way valves and circulation pumps. The system pressure is also monitored.

“The data logger function is also very interesting for us,” Bauer reports. The MFC records the heat curve over the entire production day. The data can be saved locally and viewed and analyzed clearly in tabular form.

"This gives me an overview of the processes at all times and allows me to make further optimizations based on the data."

Lothar Bauer

Thanks to its numerous communication interfaces, the MFC can be easily integrated into all systems and allows access to the data from anywhere.

Taking the wheel into your own hands

The HESCH experts at the Bauer laundry were on hand from the very beginning to provide support and advice.

"The technical support provided by HESCH is really exceptionally good."

Lothar Bauer

“After installing the heat exchangers, piping and wiring, we worked together to build the control system piece by piece. Actually, we’re not really done with that even now. We have new suggestions for improvements all the time and are still in constant contact,” reports Bauer.

Service is a top priority at HESCH. Detailed instruction in the functioning of the MFC as well as support in “programming” are therefore part of the scope of services for the automation specialist.

Modular concept with many options – not only for controlling the heat recovery system

Due to the local conditions, an extension module is used in the Bauer laundry in addition to the multifunction controller. The Fieldbus Coupler HE 5813 connects the modular Process I/O HIMOD System with a Modbus RTU network and enables an application also outside the control cabinet.

Thanks to its own intelligence, the multi-channel I/O module is able to pre-process the incoming signals from the temperature sensors. This relieves the system control. The HIMOD extension is installed in the production area, the main control system is located in the boiler house 100 meters away. Both are connected via a data line.

“This intelligent fieldbus system is of great advantage to us,” says Bauer. “It allows us to install all the control relays in the production area without having to run any more wires.” The multi-function controller from HESCH is not the first controller in the Thuringian laundry. Several PLCs from different manufacturers are already in use. But the MFC is the first controller that has convinced Bauer all along the line:

"It is easy and intuitive to operate, intelligently networked, and can be flexibly changed and expanded at any time. It's perfect for us. I can only recommend it to any laundry business."

Lothar Bauer

There is also another, positive effect: Bauer reckons with a savings potential of at least 20 percent in energy consumption.

Are you interested in a product demonstration?

Write to us or give us a call. We will be happy to arrange an appointment with you.