Optimum control of shaker filter systems – the new HE 5733 makes it possible

Longer filter service life, reliable sedimentation and short offline phases of the suction fan: The new HE 5733 shaker filter control unit from AXXERON HESCH electronics offers users many advantages. The device already contains all the necessary connections for the shaker motor and fan (up to 5 kW) and can be installed quickly.

Whether on silos, on filling systems or for workplace extraction: Shaker filters are still used in many areas, as they do not require a compressed air connection.

To ensure that the systems achieve their maximum filtration performance, regular cleaning must be controlled simply and reliably. With the HE 5733, AXXERON HESCH electronics is now launching a filter controller that is optimally adapted to the requirements of shaker filters.

With the HE 5733, system operators can increase the filter service life, as the filter pressure values can be set individually. The settling times, as long as the suction fan is not active, can also be freely selected. This ensures reliable sedimentation in the dust discharge. For mobile filters with a 400 V plug connection, there is integrated rotating field detection and phase presence monitoring.

As all components of the HE 5733 filter control unit are installed in a robust plastic housing with protection class IP65, the control unit can also be used outdoors without an additional heating element. The HE 5733 is also approved for ATEX zone 22 (dust) and can therefore also be used in areas with a briefly occurring explosive atmosphere.

The HE 5733 optionally records the differential pressure via the filter or controls the cleaning process fully automatically via the adjustable process times. The user can not only set the time for cleaning, but also the cleaning cycles and the settling time individually. Parameterization is possible via the keypad and the LED display of the control unit as well as via laptop (with connection adapter). Corresponding inputs and outputs are available for a remote start or signaling.

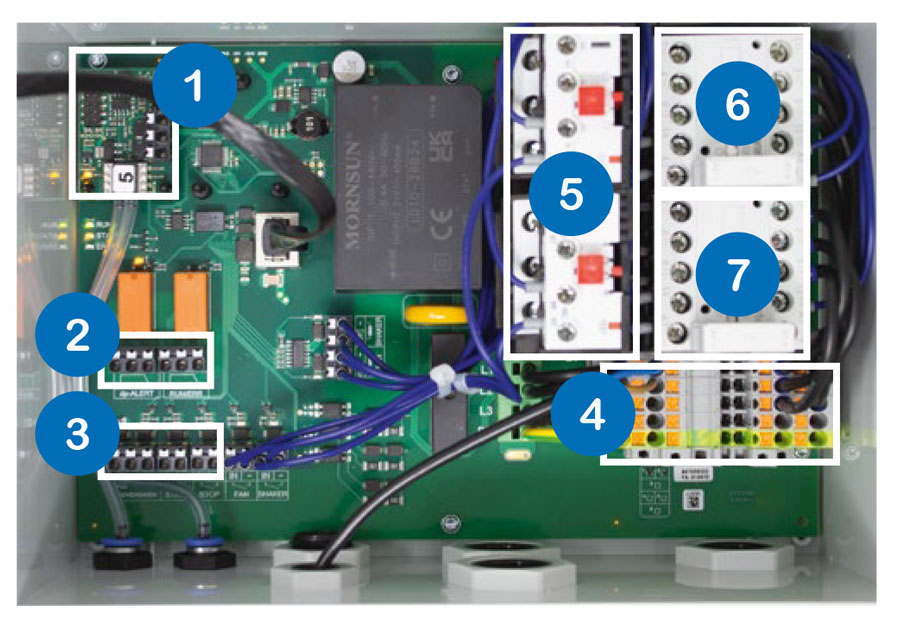

Simple connection

- Differential pressure measurement with analog outputs

- Relay outputs (operation/fault, dp alarm)

- Digital inputs

- Power supply

- Motor protection for fan and vibrator

- Power contactor for fan

- Power contactor for vibrators