Pre-pressure control increases the efficiency of filter systems

A new feature of the HE 5750 cleaning control significantly reduces compressed air costs

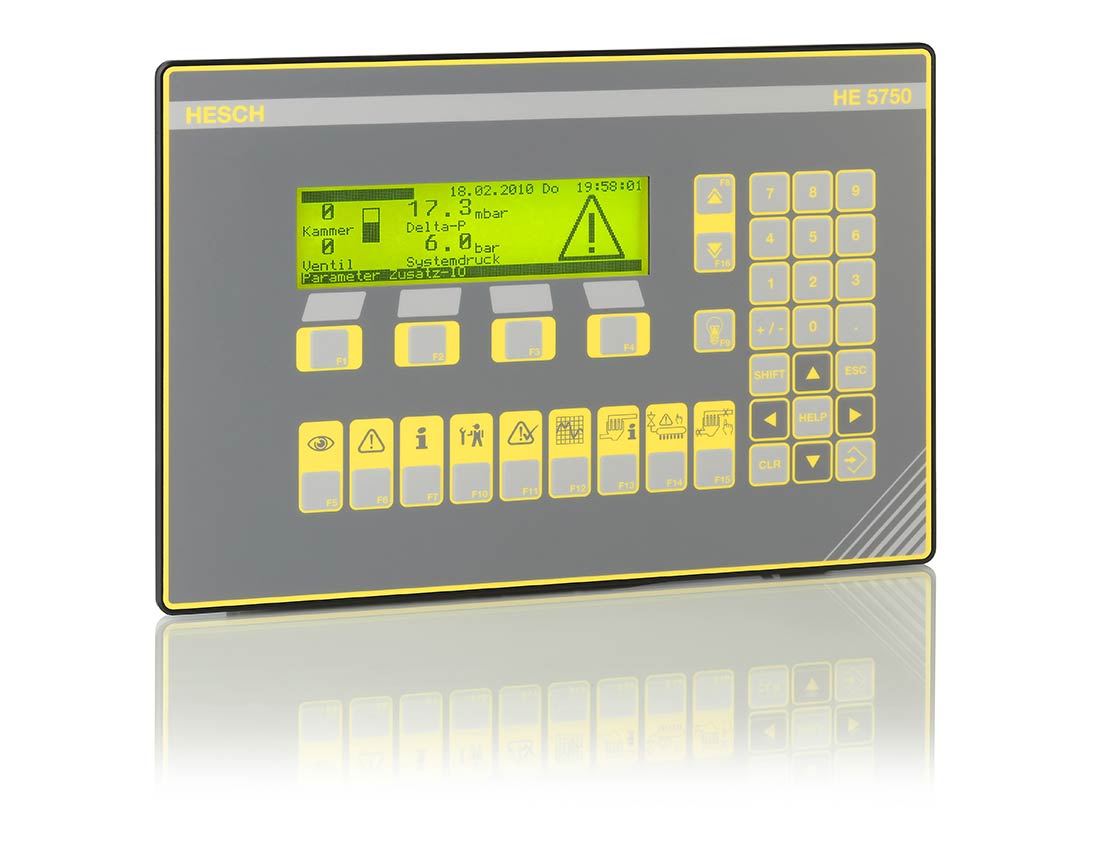

Control systems for large industrial filter systems are often poorly regulated and therefore consume more compressed air and thus energy than necessary. With the HE 5750 cleaning control system from HESCH, on the other hand, companies save money: The filter control system pulses the valves depending on the load and thus optimizes them to meet demand. In addition, the HE 5750 now offers further intelligent functions such as “pre-pressure control”, with which compressed air consumption can be reduced even further.

Saving energy costs is more important than ever and the industry is looking for ways to reduce energy consumption. With its HE 5750 cleaning control system, automation specialist HESCH offers operators of large filter systems an energy-saving alternative to conventional systems. These are often outdated and also often only clean the filters with fixed thresholds and thus inefficiently.

The HE 5750, on the other hand, only triggers cleaning when the degree of contamination of the filter really requires it. This already allows operators to significantly reduce their energy costs. Now HESCH is launching two more features for the HE 5750, the “changeover unit” and the “pre-pressure control”: on the one hand, they increase system availability and, on the other hand, enable even more economical operation of the filter system for air pollution control.

With the new inlet pressure control, the cleaning pressure is optimized depending on the load. The control ensures that only as much compressed air is delivered as is necessary for cleaning the filter. This control is performed by a simple central valve in the compressed air supply line. By precisely adjusting the cleaning pressure to the current demand, not only the costs for compressed air are significantly reduced. The filter media also have a longer service life, as they are subjected to compressed air at low loads far more gently than before. Thus, the new inlet pressure control of the HE 5750 also increases the service life of the filter elements. Another advantage of the innovative control function is that it minimizes the consumption of precoating agents. This auxiliary layer is applied to filter media, e.g. to improve cleaning performance. Since the intelligent control system optimally adapts the number of cleaning pulses and the cleaning pressure to the degree of contamination of the filter, the precoating layer is retained for longer. Automatic hose rupture monitoring and monitoring of the cleaning valve function also help to increase the availability of filter systems.

New changeover unit enables redundancy system to be set up

Together with the pre-pressure control, HESCH has also developed a “changeover unit” that can be used to increase plant availability. The changeover unit is intended for use in redundancy systems with two HE 5750 master controllers and has the task of switching the CAN slave periphery to one of the two master controllers in each case.

The switchover unit copies the process image and the current parameters from the active HE 5750 master to the HE 5750 master in standby mode. Thus, the changeover unit ensures consistent data for parameters, process image and chamber switching on the two connected HE 5750 master controllers. This copying process also serves to monitor the connected HE 5750 master controls for their function or for the presence of the master control. If the active master control now fails due to a defect, the system automatically switches to the stand-by control, which then seamlessly takes over the active master function with current data. At the same time, a warning message is sent. The operating personnel can then promptly replace the defective control without interrupting operation.