HE 5712 – Valve control in compact housing

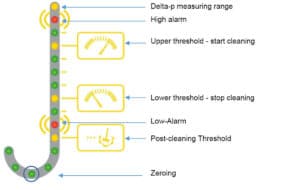

The HE 5712 enables the time or differential pressure dependent control of up to 8 solenoid valves in industrial dust removal technology. The valves are activated sequentially and monitored for overcurrent and interruption. The differential pressure is measured directly by the controller, so no external sensor is required.

Intuitive operation

The language-independent symbol labelling enables the control system to be used worldwide.

- Clear status display with LEDs

- Simple operation without complicated menu structures

Convenient parameterization

The control system can be parameterized via the membrane keypad or optionally with the EasyTool Controls software. With EasyTool Controls, parameter data sets can be transferred to the controller easily and quickly. This is particularly convenient and time-saving when a number of controllers have to be recorded with the same data sets.

Practical: Flexible mounting for reduced cabling

The modular concept of the HE 5712 allows the control unit to be mounted separately from the operating unit. The control unit can be mounted up to 100 meters away from the control unit so that the control unit is in the user’s field of vision. This means he always has the status display in view and can react quickly if necessary. The control unit with the valve connections remains close to the valves, which significantly reduces the amount of cabling required.

The separately available connection set with matching cable glands and the pre-assembled cables with valve plugs in various lengths are a useful addition to the control system.

Illustrations show HE 5712 filter control unit with connection set #57120088