HE 5733 shaker filter controller for use in shaker filter systems

Shaker filter controller for optimum operation of the filter system

The HE 5733 optionally records the differential pressure via the filter or controls the cleaning process fully automatically via the adjustable process times.

The user can not only set the time for cleaning, but also the cleaning cycles and the settling time individually. Parameterization is possible both via the keypad and the LED display of the shaker filter controller, as well as via laptop with connection adapter and the EasyTool Controls 4.0 software.

Simple connection and quick commissioning

A switching input is available for a remote start, as well as two switching outputs for fault and differential pressure alarm. The quick and easy commissioning is particularly interesting – all the necessary connections for the fan, shaking motor and release signal are integrated in the device. No additional contactors or similar are required.

All components are built into a robust IP65 plastic housing, which can also be used outdoors without additional heating thanks to its special design.

The housing of the shaker filter controller is particularly easy to service and install. Thanks to the hinged lid, only a slotted screwdriver is needed to open the device. This saves time compared to standard housings which are closed with 4 screws. Optionally, the additional lock with 4 screws is also possible to protect the device from unauthorized access.

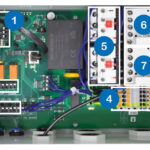

Shaker filter controller interior view

- Differential pressure measurement with analog outputs

- Relay outputs (operation/fault, dp alarm)

- Digital inputs

- Power supply

- Motor protection for fan and vibrator

- Power contactor for fan

- Power contactor for vibrators

Shaker filter controller with language-independent operation for worldwide use

The importance of vibrator control in shaker filter systems:

Shaker filters are regenerative fabric filters with mechanical cleaning. Cleaning is carried out with the aid of a motor-driven oscillating device. This requires a suitable Shaker filter controller that enables automatic cleaning when a max. The motor is switched on by the differential pressure across the filter (filter resistance) or after a defined time and causes the filter elements to vibrate. The filter cake detaches from the filter fabric and falls into a sedimentation tank.

This cleaning process can only be carried out when the suction fan is switched off (offline cleaning). This non-active time of the suction fan (settling time) must also be specified by the Shaker filter controller and depends on the dust fineness or system design. The correct settling time prevents the process gas from recapturing the falling dust.